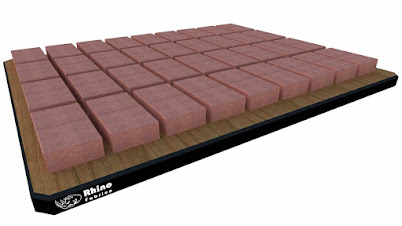

High-Grade Pallets for Concrete Blocks Online

Pallets have emerged as indispensable components in the realm of block machine operations, revolutionizing the efficiency and quality of the construction industry. These flat, often wooden or plastic structures provide crucial support during the manufacturing of concrete blocks, enhancing the overall production process. Depending on your requirement, you can choose the best range of pallets for concrete blocks to carry them easily and in safe way. For the best range of pallets for concrete blocks , what all you have to do is search for the top manufacturers, go through the details of such pallets and then place your order accordingly. The best way is searching for the top companies online. There are a number of recognized names in this domain providing you with complete peace of mind. You can contact from anywhere and anytime. Online search is an ideal way to save you time and provide you with some better option to fulfill your requirement. You can contact from anywhere and anytime and...